IoT remote monitoring lets you track systems from anywhere, anytime. It uses IoT devices and sensors to collect real-time operational data. These systems send alerts when something goes wrong or needs attention. That means you can act fast, often before major problems even happen. Remote monitoring solutions reduce the need for on-site inspections. They also minimize equipment failure, costly repairs, and unplanned downtime.

IoT catches issues early to improve uptime and overall system health. Plus, teams get remote access to real-time data via dashboards. It helps in managing smart buildings to a remote fleet. IoT monitoring brings visibility to places you couldn’t easily reach before. It also cuts manual checks and optimizes how devices operate daily. With the right IoT monitoring solution, you automate and save more. It’s a smarter way to boost efficiency, website security, reduce costs, and stay ahead.

What Is an IoT Remote Monitoring System?

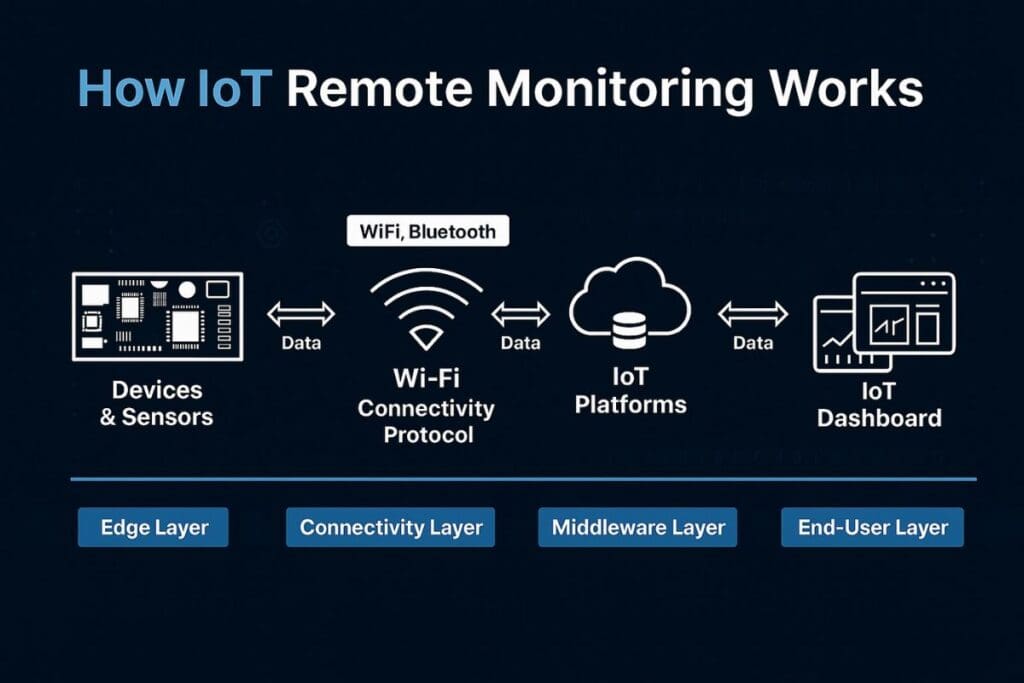

An IoT remote monitoring system collects and tracks data in real time. It uses sensors and IoT devices to monitor conditions and equipment status. These devices operate 24/7, feeding data into a central monitoring system. Data helps businesses detect issues early and take quick action remotely.

Devices connect to the internet using different technologies. Common options include:

- Cellular: Ideal for remote locations without stable internet access

- WiFi: Great for on-site systems with strong network availability

- Edge Computing: Processes data closer to the device, reducing latency

Once data is collected, it flows to an IoT platform. It organizes info and sends alerts when thresholds are crossed. Users view the data on dashboards through desktop or mobile devices.

These dashboards provide real-time insights, graphs, and system health reports. Some platforms also support automation and advanced analytics tools. This helps teams predict failures and prevent downtime before it happens. Many solutions even offer historical data for performance trends and reporting. IoT remote monitoring enables smarter decision-making across many industries. It simplifies device monitoring while improving safety, reliability, and operational control.

IoT Remote Monitoring vs. Traditional Systems

Remote IoT monitoring changes how businesses track assets, equipment, and systems. Unlike legacy setups, IoT enables proactive, real-time control from any location.

Here’s how both systems compare across key operational areas:

| Feature | Traditional Monitoring | IoT Remote Monitoring |

|---|---|---|

| Data Collection | Relies on scheduled inspections or manual input | Streams continuous data automatically from sensors in real time |

| Accessibility | Users must be physically present to retrieve data | Remote dashboards allow access from any internet-enabled device |

| Data Analysis | Often done by hand or using basic tools | Uses cloud-based analytics for deeper insights and faster decisions |

| Scalability | Challenging to expand across multiple sites or assets | Easily supports more devices across various environments |

| Maintenance | Needs frequent sensor checks and manual replacements | Smart devices alert users only when maintenance is necessary |

| Cost | Higher upfront costs for hardware and frequent servicing | Long-term savings from automation and reduced field service |

IoT offers more than just data; it delivers automation, efficiency, and scale. As systems grow more complex, IoT makes remote monitoring simpler and smarter.

Key Components of a Monitoring Solution

A reliable IoT remote monitoring solution has several core components. Each plays a key role in capturing, transmitting, and analyzing real-time data.

IoT Sensors and Devices

Sensors collect environmental or equipment data like temperature, pressure, or location. They attach to machines, systems, or infrastructure to collect real-time values. Each IoT device sends this data for processing, triggering alerts if needed.

Connectivity Options

IoT sensors need stable communication links to send remote data. Common choices include cellular, Wi-Fi, Ethernet, or low-power IoT networks. Edge computing can help reduce latency and bandwidth by processing data locally.

Analytics and Dashboards

Collected data is sent to the IoT platform for analysis. Dashboards give users access to real-time alerts and historical trends. This helps identify issues early and enables predictive maintenance.

Remote Management Tools

Monitoring software enables remote control and management of connected devices. Users can update firmware, troubleshoot issues, and manage device performance remotely. This reduces the need for on-site visits and improves operational efficiency.

Essential Parameters Tracked by IoT Monitoring Systems

IoT remote monitoring platforms help track asset conditions from any location. They collect real-time data and send alerts to prevent unexpected issues. Here are the key parameters these systems monitor to boost efficiency.

Temperature Monitoring

- Tracks temperature in machines, storage units, and outdoor environments.

- Prevents overheating of equipment in manufacturing and data centers.

- Ensures cold storage and agriculture stay within optimal temperature levels.

Pressure Monitoring

- Detects pressure changes in pipelines, tanks, and fluid systems.

- Prevents leaks, bursts, or hazardous pressure buildup in industrial settings.

- Helps ensure safe, continuous operations in oil, gas, and chemical plants.

Fill Level Monitoring

- Monitors fuel tanks, silos, and liquid storage containers.

- Supports inventory planning with automated refill alerts and tracking.

- Avoids overflows, shortages, and unnecessary manual checks.

Vibration Monitoring

- Identifies irregular vibrations in motors, engines, and rotating equipment.

- Detects early signs of mechanical failure for predictive maintenance.

- Minimizes downtime by scheduling timely repairs before breakdowns happen.

Location Tracking

- Tracks mobile assets like vehicles, machines, or livestock.

- Improves logistics coordination with real-time location data.

- Secures assets and enables better fleet and inventory control.

Top Advantages of Using IoT Remote Monitoring Systems

IoT remote monitoring helps businesses track assets, conditions, and performance. It reduces guesswork by delivering real-time insights from connected devices. Below are the most important benefits of implementing IoT monitoring solutions.

Improved Sustainability and Efficiency

IoT sensors help reduce waste by automating and optimizing key processes. Preventive maintenance reduces service calls, saving fuel and technician time. Better control over operations leads to smarter use of resources daily.

Real-Time Insights

Real-time data shows what’s happening with assets. Alerts let teams act fast before minor issues grow into big problems. Dashboards display key trends for quick and smart responses.

Faster Response Time

Remote alerts allow teams to act the moment problems begin. No need to wait for on-site reports or manual inspections. Faster decisions lead to less damage and more uptime.

Less Downtime

Detects equipment failure risks before systems break down. Schedule repairs before operations are disrupted by breakdowns. Continuous monitoring keeps critical assets running longer.

Better Customer Service

Service teams can troubleshoot issues without on-spot visiting. Customers benefit from quick fixes and less surprise outages. Preventative repairs reduce the need for emergency calls.

Lower Operational Costs

IoT systems help extend equipment life and reduce repair frequency. Optimized energy use lowers electricity and resource bills. Fewer service visits also translate into labor cost savings.

Data-Driven Decisions

Real-time data builds a reliable picture of operational performance. Historical data helps spot trends and recurring issues. Leaders can make smarter decisions based on solid evidence.

Increased Safety and Security

Sensors monitor temperature, gas, or motion to prevent unsafe conditions. Alerts trigger for any security breach or hazard. Remote surveillance protects facilities without on-site presence.

Protect Inventory

Sensors monitor temperature and humidity to preserve perishable items. Location tracking prevents asset loss or theft. Alerts ensure inventory stays safe, secure, and within thresholds.

Analyze Equipment Performance

Monitor device behavior to find underperforming machines or bottlenecks. Optimize usage with insight into wear, output, or idle time. Extend asset life with improvements and fine-tuning.

Track and Manage Field Assets

Monitor trucks, machines, or tools even in remote locations. Know where assets are and how they’re performing anytime. This helps dispatch teams and resources more efficiently.

Reduce Manual Labor

No more paper logs or repeated rounds for data checks. IoT automates reports, alerts, and system diagnostics. Teams focus on strategic work, not routine monitoring.

Smarter Space Allocation

Sensor data shows which areas are overused or underutilized. Optimize warehouse layout to store fast-moving goods better. Use data to unlock space without costly expansions.

Efficient Inspections and Maintenance

Base inspections on data, not on fixed time intervals. Spot potential failures early and avoid unnecessary checks. Maintenance becomes more proactive, not reactive.

Full Operational Visibility

IoT systems collect data from across the operation. Gain a 360-degree view of your business in real time. Identify bottlenecks and optimize processes company-wide.

Higher First-Time Fix Rate

Technicians get diagnostics before reaching the site. They arrive prepared with correct tools and replacement parts. Fixing issues on the first visit saves time and cost.

Popular Use Cases of IoT Remote Monitoring

IoT remote monitoring is helping many industries work smarter and faster. It gives real-time updates that help teams act before problems grow.

Manufacturing

Sensors track machine temperature to avoid overheating and breakdowns. Vibration data helps detect faults before costly failures happen. Inventory sensors monitor stock and trigger restocking on time.

Smart Buildings

Smart thermostats control climate and reduce energy use daily. Leak sensors prevent damage from burst pipes or faulty plumbing. Remote surveillance boosts safety with instant alerts and monitoring.

Agriculture

Soil sensors guide irrigation to save water and grow healthier crops. Weather data helps farmers prepare for storms or drought. GPS trackers monitor livestock location and prevent loss.

Logistics and Supply Chain

Track vehicles and shipments in real time to improve routing. Sensors keep goods safe in proper temperature and humidity.

Healthcare

Wearables monitor vital signs and send alerts for early care. Sensors ensure medical equipment stays functional and well-maintained.

How to Choose the Right IoT Platform and Deployment Model

Choosing the right IoT platform affects performance, data security, and flexibility. It also helps you manage devices, data, and updates more efficiently.

Edge vs. Cloud-Hosted

Edge platforms process data closer to the devices themselves. They offer faster response times and work even during internet loss. Cloud-hosted platforms send data to remote servers for storage and analysis. They’re easier to scale and require less on-site infrastructure.

Device Management and Scalability

The right platform should support thousands of devices with ease. It should allow remote software updates and real-time health monitoring. This helps reduce downtime and avoids manual site visits.

Hybrid or On-Prem Options

Some businesses need a mix of cloud and on-premises control. Hybrid platforms offer more flexibility for security or compliance reasons. Choose one that adapts to both current and future needs.

Steps to Implement an IoT Remote Monitoring Solution

Implementing IoT remote monitoring starts with a clear, step-by-step plan. Each stage should focus on real-time data, automation, and quick action.

1. Sensor Deployment

Install IoT sensors on equipment, assets, or critical infrastructure points. Choose sensors based on what conditions you need to monitor daily. Common options include temperature, vibration, pressure, and location sensors.

2. Data Collection

Sensors collect data and send it to a centralized platform. Use reliable connectivity: Wi-Fi, cellular, or edge networks for smooth transmission. Collected data flows continuously, giving real-time visibility into your operations.

3. Alert Configuration

Set thresholds for each parameter using historical and industry benchmarks. When a reading exceeds the threshold, automatic alerts are triggered. You can get alerts via email, SMS, or through a dashboard.

4. Automated Actions

Configure automated responses like equipment shutdown or backup activation. Remote diagnostics help identify issues without sending a technician on-site. This reduces response time and improves service quality significantly.

5. System Integration

Link your IoT solution with ERP, CMMS, or workflow systems. This makes it easier to act on alerts without switching platforms. Integration also ensures data is used for decision-making across departments.

6. Build a Monitoring Checklist

Use a checklist to track metrics, updates, and alert frequency. It helps maintain consistency, efficiency, and compliance across your operations. Plan thoroughly to ensure your IoT system is future-ready and effective.

Challenges and Best Practices for IoT Remote Monitoring

IoT remote monitoring brings value but also comes with challenges. You need a smart plan to avoid issues and scale effectively.

Common Challenges

- Connectivity Issues: Unstable internet disrupts real-time data collection and alerts.

- Security Risks: Weak systems are vulnerable to hacks and data breaches.

- Data Overload: Too much data makes analysis slow and decision-making harder.

Best Practices

- Use Strong Encryption: Protect all transmitted data with end-to-end encryption.

- Access Control: Limit access to dashboards with role-based user permissions.

- Firmware Updates: Regularly update device firmware to patch security gaps quickly.

Plan for Scalability

- Choose platforms that support thousands of devices with ease.

- Use cloud or hybrid systems to grow without hitting technical limits.

- Automate data sorting and alerts to stay efficient as devices increase.

Conclusion

IoT remote monitoring boosts resilience, efficiency, and long-term ROI. It reduces downtime, prevents failures, and streamlines operations across industries. Real-time insights help you respond faster and make smarter decisions daily. From manufacturing to healthcare, the benefits apply to every modern business.

Rekall Tech offers expert IoT deployment, integration, and ongoing support. Our team helps you build a reliable, scalable monitoring infrastructure. We handle everything: from sensor setup to platform management and diagnostics. Ready to future-proof your operations? Partner with Rekall Tech today and unlock the power of IoT.